Synthetic oligonucleotides (oligos) are central to many cutting-edge biochemical applications across research and therapeutics. While solid-phase synthesis typically yields oligos with relatively high purity, they usually need further purification to avoid unintended side-reactions and interferences in downstream applications. In many of these applications, a very high level of purity is required — for example, in therapeutics or in real-time qPCR probe production.

Many prep HPLC systems are available for oligo purification, with the simplest consisting of three components:

HPLC systems vary in size, complexity, and capability. To increase productivity and maximize the profitability of your oligo research and development, finding the optimal LC purification platform is crucial.

When choosing an HPLC system for oligo purification, there are seven key factors that you need to consider:

- Oligonucleotide Length and Downstream Application

Your oligonucleotide products are the major factor that will influence the type of purification you need. For example, longer oligos require a higher number of synthesis cycles to make. As a result, these syntheses will contain larger concentrations of undesirable byproducts and residual starting material that need to be removed.

Multiple HPLC techniques are available, with the most common being anion-exchange (AEX)-HPLC and ion-pair reversed phase (IP-RP)-HPLC. But which should you choose? The answer depends on the product:

- AEX-HPLC uses the negative charge difference between full-length and truncated oligos to separate them, so it is suitable for unmodified oligo purification.

- IP-RP HPLC uses intrinsic hydrophobicity differences between the failure sequence and the full-length sequence. IP-RP HPLC can also distinguish failed vs. successful modifications of full-length sequences. As such, this technique is suitable for both modified and unmodified oligos (with Trityl on) < 40 bp in length.

However, many labs find that they need to combine HPLC purification techniques to reach their desired purity. Therefore, when choosing a HPLC purification platform, it’s important to consider whether the system can perform:

- Orthogonal HPLC techniques (e.g., AEX and IP-RP HPLC) to save time, increase efficiency, and limit the number of HPLC systems in your lab

- A final size exclusion chromatography (SEC) step to desalt or remove the ion-pairing agent (e.g., TEAA) from the purified oligo fractions

- Sample Volume / Mass

The volume and the mass of the oligos to be injected will determine the choice of the HPLC column diameter(s) to use on your system — the wrong diameter will not deliver sufficient capacity. Considering these factors will also allow you to pick the right HPLC binary pumping system in terms of flow rate range and the size of injection loops to be used by the system.

- Reliability

Reproducibility and accuracy are significant concerns for many labs that purify synthesized oligos because they can directly impact the final products' yield and purity.

Consider whether the prep HPLC has:

- A gradient pump capable of accurately and consistently producing a gradient in the working range of flow rates and composition of the mobile phase

- A detection system compatible with your working range of concentrations and is able to perform multi-wavelength acquisition to adapt to oligonucleotide concentrations

- Automation to enable accurate and reproducible injections and timely fraction collection

- Different collection modes that maximize fraction purity, including collection by time, slope, level, and use of conditional collection operators (such as AND, OR, and NOR)

Finally, you need to determine the key parameters you would like to control during the process to ensure the quality and safety of your products. For example, for the HPLC system itself, you may look for automated systems with advanced error handling to secure your purification in case something goes wrong. Some considerations are chromatography-specific: you may need to control the gradient buffer quality during AEX purification or the quality of desalting during SEC using an online pH conductometer.

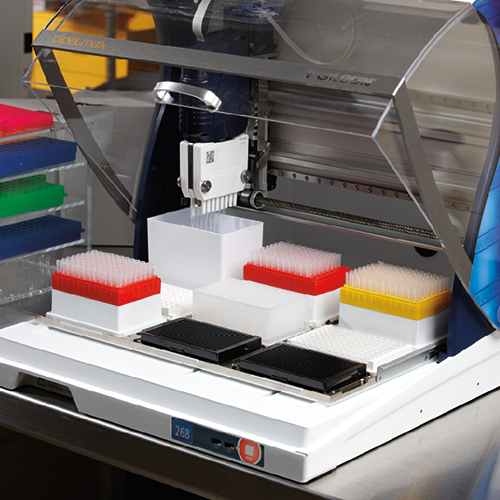

- Throughput / Automation

Purification is a critical bottleneck in oligo synthesis. Automation can overcome this challenge, making purification more efficient and less error-prone. To select the ideal automated oligo purification platform, you need to identify which steps of the process would benefit from being automated.

First, determine the size of the liquid handler you need by calculating how many samples you will need to inject. While larger liquid handlers are better for labs that require higher throughput and multiple fractions per sample, they can come with an increased footprint.

Next, determine if more than one injection module would benefit your desired workflow. Having two injection modules on a single liquid handler means you can cover a wider range of volume injections of crude oligos while avoiding injecting highly concentrated samples, which can risk precipitation and sample loss.

Similarly, consider automated valve selectors, which allow you to minimize the downtime in the purification workflow by enabling automated selection of the following columns according to your needs:

- An analytical column to control your collected fractions

- Purification columns (IP-RP, AEX, or SEC) and associated mobile phases depending on the purification step and scale up

- A desalting column

Finally, consider a system that enables automatic column regeneration. Automatic column regeneration can increase throughput and maximize the ROI for your new system.

- Flexibility / Upgradability

For many labs, their workflow will change over time. If this is likely to happen in your lab, you will need a flexible and/or upgradable system that can accommodate this. Typically, modular systems can help accommodate changing requirements.

- Software Features

Software makes an important contribution to how suitable an LC platform is for your workflow. HPLC software should be:

- Intuitive and easy to use

- Compliant with your collection modes, flexibility, and upgradability needs

- Able to safely control your system with smart alarm management

- Capable of ensuring experiment trackability

- Support Services

For some labs, high vendor support is crucial, whereas others may just need basic support. When selecting your instrument, factor in what level of customer service the vendor provides before, during, and after purchase and what support fits you and your budget.

There are clearly many crucial factors to consider when choosing an oligo purification system, and balancing these can be tricky. Now, there is a flexible system available that takes these considerations into account and makes it simple to optimize your oligo purification workflow.

For labs to maximize productivity and profitability of their oligo research and development, they must optimize their purification workflow and ensure they have the right system in place. Choosing a platform for oligo purification means the careful consideration of many factors, including what your products are and any future requirements for throughput and scale.

Ready to learn more about the VERITY Oligo Purification System? Request a quote or contact us to arrange a demo.